1930s Wilson Memindex Co Index Card Organizer Pre Rolodex Ad Price List Brochure

archived page: https://web.archive.org/web/20230310010450/https://www.ebay.com/itm/165910049390

Includes price lists

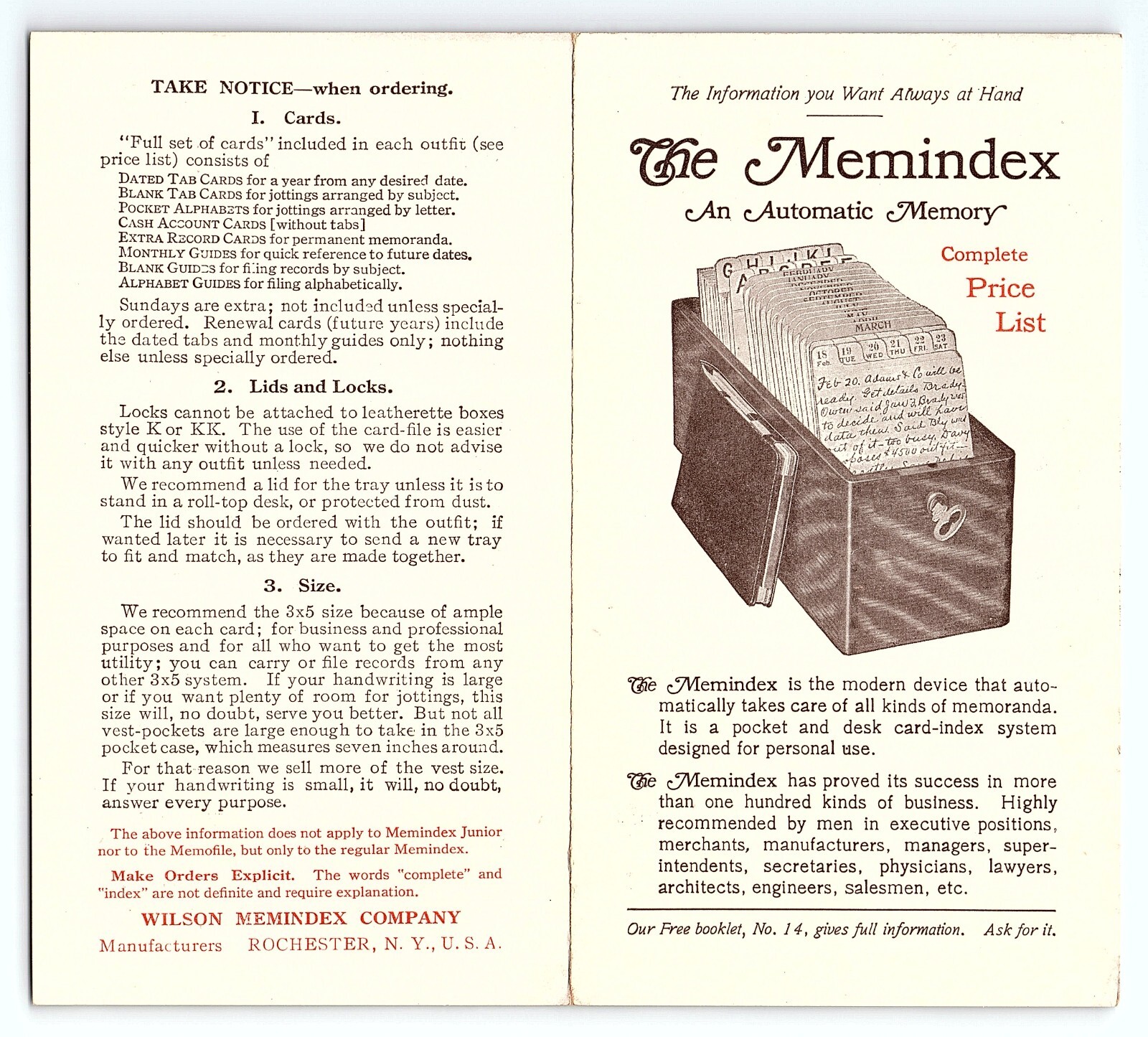

List of cards includes:

- Dated tab cards for a year from any desired.

- Blank tab cards for jottings arranged by subject.

- These were sold in 1/2 or 1/3 cut formats

- Pocket Alphabets for jottings arranged by letter.

- Cash Account Cards [without tabs].

- Extra Record Cards for permanent memoranda.

- Monthly Guides for quick reference to future dates.

- Blank Guides for filing records by subject..

- Alphabet Guides for filing alphabetically.

Memindex sales brochures recommended the 3 x 5" cards (which had apparently been standardized by 1930 compared to the 5 1/2" width from earlier versions around 1906) because they could be used with other 3 x 5" index card systems.

In the 1930s Wilson Memindex Company sold more of their vest pocket sized 2 1/4 x 4 1/2" systems than 3 x 5" systems.

Some of the difference between the vest sized and regular sized systems choice was based on the size of the particular user's handwriting. It was recommended that those with larger handwriting use the larger cards.

By the 1930's at least the Memindex tag line "An Automatic Memory" was being used, which also gave an indication of the ubiquity of automatization of industrialized life.

The Memindex has proved its success in more than one hundred kinds of business. Highly recommended by men in executive positions, merchants, manufacturers, managers, .... etc.

Notice the gendering of users specifically as men here.

Features:

- Sunday cards were sold separately and by my reading were full length tabs rather than 1/6 tabs like the other six days of the week

- Lids were custom fit to the bases and needed to be ordered together

- The Memindex Jr. held 400 cards versus the larger 9 inch standard trays which had space for 800 cards and block (presumably a block to hold them up or at an angle when partially empty).

The Memindex Jr., according to a price sheet in the 1930s, was used "extensively as an advertising gift".

The Memindex system had cards available in bundles of 100 that were labeled with the heading "Things to Keep in Sight".